Upstox Originals

Beyond the assembly line: How IoT is reshaping manufacturing

.png)

7 min read | Updated on August 07, 2025, 19:23 IST

SUMMARY

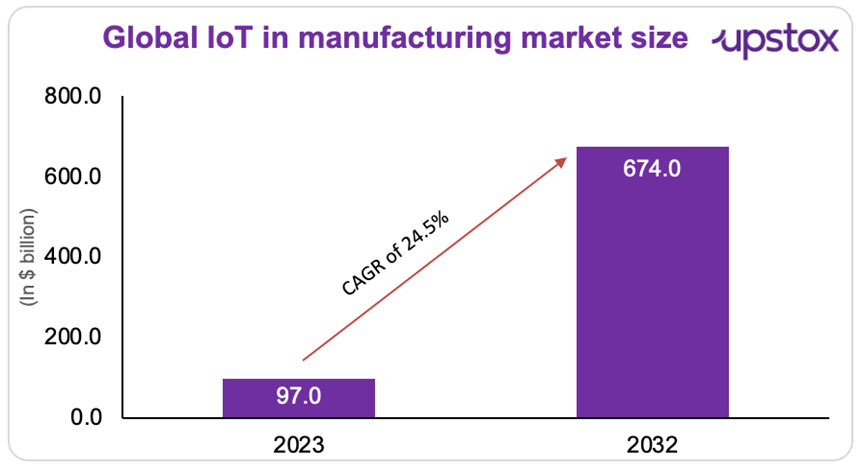

Factories today are evolving beyond human-led production lines to intelligent systems powered by IoT. From sensors tracking products to machines predicting failures, IoT in manufacturing is transforming how industries operate. The global market, worth $97 billion in 2023, is on track to grow nearly 7x by 2032. This shift is reshaping competitiveness, efficiency, and innovation worldwide.

The global IoT market is expected to grow nearly 7x by 2032

Imagine a factory where machines talk to each other, predict failures before they happen, and optimise processes without human intervention. That’s not science fiction – it’s Internet of Things (IoT) in manufacturing in action.

Why are we talking about it now? In just a few decades, it has gone from basic sensors to becoming the beating heart of production, transforming scale, speed, and efficiency worldwide.

Let us take a look at the global IoT in manufacturing market:

Source: Fortune Business Insights

- Regional trends: North America led with 30.7% share and 33.3% of 2024 revenue; Asia-Pacific is close behind with a 25.6% CAGR (2025–2030). Europe holds steady, driven by Industrie 4.0 and Alliance Industrie du Futur.

- Component & services: In 2024, software led with 51% market share, while services are set to grow fastest at 23.6% CAGR (2025–2030).

- Industry demand: Automotive & EVs topped with 21.4% share in 2024; pharma & life sciences to grow at 27.2% CAGR. Factory floors are also seeing rising demand for sensors, controllers, and gateways.

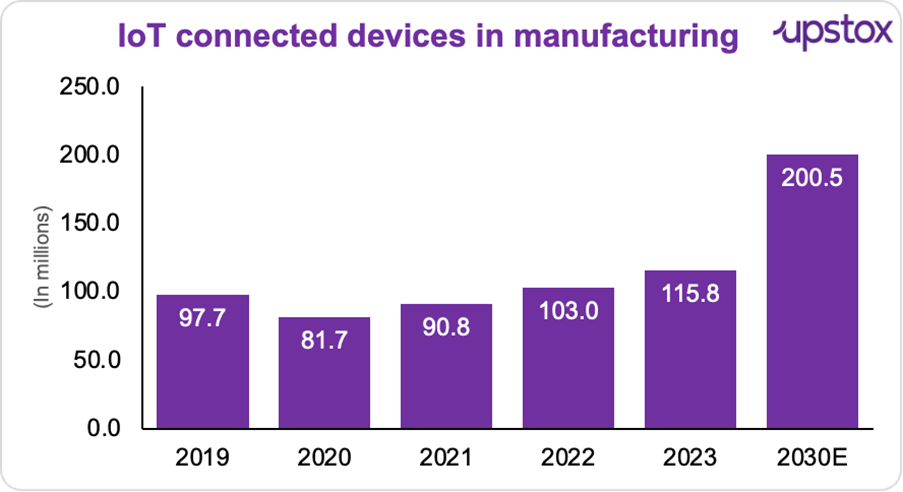

The growth of IoT in manufacturing is also shaping demand for connected devices ( like sensors, controllers, and industrial gateways) on the shop floor:

Source: Market and markets

A journey through time: IoT evolution in manufacturing

| Decade | Event |

|---|---|

| 1960s | Sensors in factories |

| 1970s | PLCs replaced relays |

| 1980s | Industrial robots |

| 1990s | ERP systems arrived |

| 2000s | Industry 4.0 coined |

| 2010s | 3D printing & additive manufacturing |

| 2020s | AI, edge, and digital Twins |

What is IoT in manufacturing?

IoT in manufacturing integrates sensors, devices, cloud platforms, and analytics into production environments, enabling real-time monitoring, predictive maintenance, and process optimisation. It’s like giving factories a nervous system and a brain, making operations smarter, safer, and far more efficient.

How much does it cost?

The cost of developing an IoT solution for manufacturing varies widely based on complexity, hardware, software, data management, and scalability needs.

-

Basic proof of concept: ~$5,000

-

Simple solutions (few sensors): <$50,000

-

Complex large-scale systems (many sensors, actuators, real-time streaming): up to $1 million or more

Costs also depend on factors like network connectivity type and infrastructure choices.

Use cases and applications

IoT is transforming manufacturing with practical solutions that boost efficiency, cut costs, and keep operations running smoothly. Here are the top use cases driving this change:

| Use case | What it does | Real-world example |

|---|---|---|

| AI predictive maintenance | Helps fix machines before they break down | Tata Steel uses AI-driven sensors in its Jamshedpur plant to predict equipment failures and reduce downtime. |

| Digital twins | Creates virtual models of factories to test and improve performance | Siemens uses digital twins in its Amberg facility to simulate and optimize production lines. |

| IoT energy management | Cuts energy bills by tracking usage in real time | Bosch implemented IoT-based energy monitoring at its Bengaluru plant to reduce electricity costs by 15%. |

| Process automation | Keeps operations running smoothly with minimal human input | Foxconn employs robotic process automation (RPA) and IoT to streamline iPhone assembly lines. |

| Remote asset monitoring | Lets companies check on machines from far away | L&T uses remote IoT dashboards to monitor construction equipment performance across sites in real time. |

Source: News articles

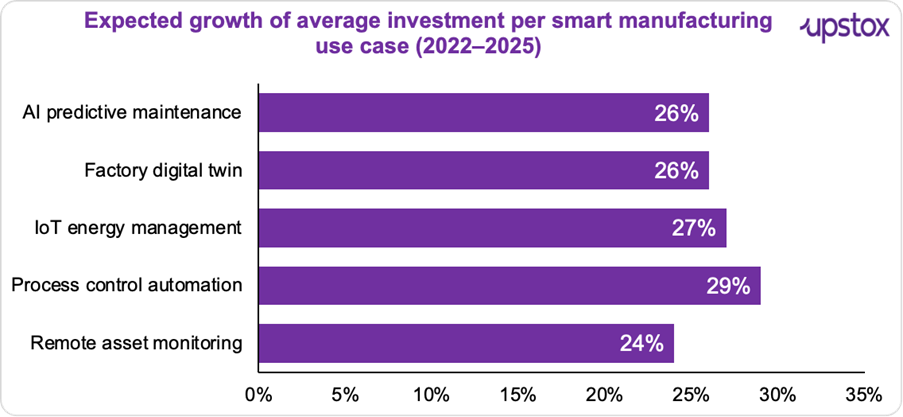

But which smart manufacturing use cases are seeing the biggest investments between 2022 and 2025? The chart below shows where manufacturers are directing their spending the most.

Source: Lemberg solutions

Why is IoT in manufacturing important?

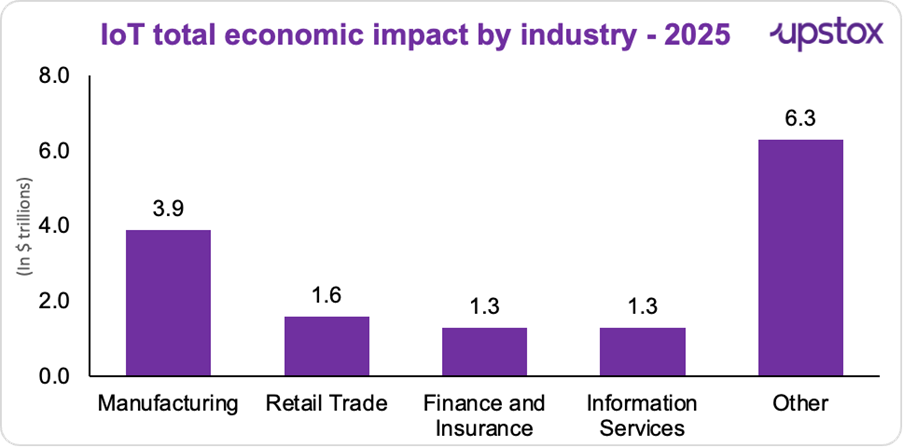

Greater economic impact

As of 2025, McKinsey estimates that IoT applications in manufacturing are generating trillions annually. Looking ahead, manufacturers are doubling down on smart tech, with global spending on Industry 4.0 expected to reach $276 billion by 2029, according to Research and Markets.

Source: Cisco

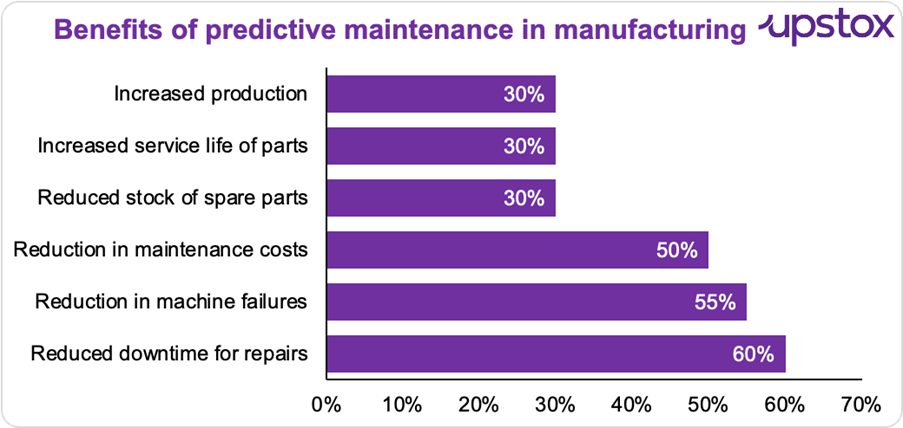

Predictive Maintenance

Machine downtime is every manufacturer’s nightmare. On average, manufacturers face 800 hours of equipment downtime each year, costing the industry a massive $50 billion annually in unplanned expenses. What’s driving these losses? Simply put – lack of proper predictive maintenance.

Source: Lemberg solutions

Predictive maintenance tracks machine data like temperature, vibration, and pressure in real time. AI and ML analyse this to catch problems early – before they turn into costly breakdowns..

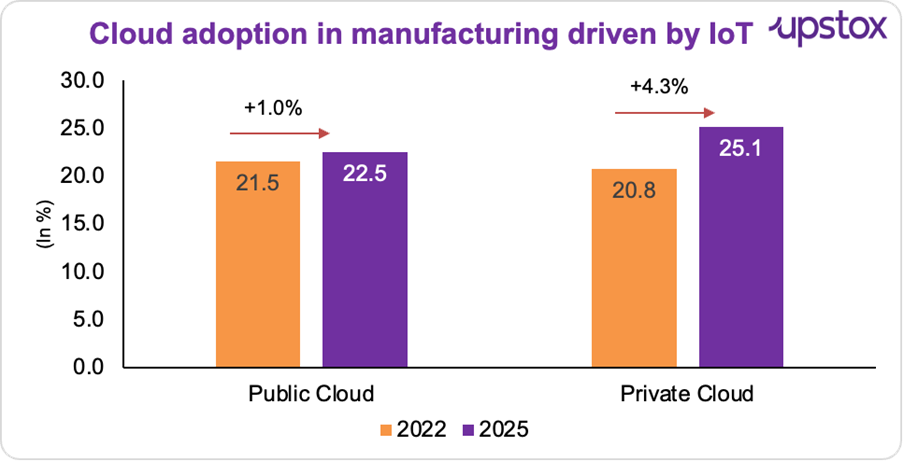

Transition to the cloud

IoT is helping manufacturers adopt cloud solutions for faster insights and improved efficiency. This adoption enhances operations by making factories more agile and connected.

Source: Lemberg Solutions

Worker safety

IoT sensors capture real-time shop floor data and send it to the cloud for quick analysis, helping manufacturers spot and prevent safety hazards. For instance, HVAC sensors monitor air quality while AQI software ensures it stays safe. FaceMe’s facial recognition tech alerts when workers don’t wear masks properly - crucial during COVID-19. With workplace injuries costing $170 billion annually, IoT can greatly reduce health and liability risks.

Energy efficiency

Did you know IoT can cut your factory’s energy bills? Take Armal, a portable toilet manufacturer, by using real-time IoT monitoring on their production line, they slashed machinery energy costs by nearly 40%.That’s not just savings – it’s a big step towards smarter, more sustainable manufacturing.

Global giants using IoT

Volkswagen x AWS

Volkswagen, producing 11 million cars yearly, built its Industrial Cloud with AWS to modernise manufacturing and logistics. Integrating data from 120+ factory sites enables real-time insights, targeting 30% productivity gains, 30% reduction in factory costs, and €1 billion supply chain savings.

Unilever x Microsoft

Unilever teamed up with Microsoft to create digital twins of factories. Machinery sends constant data to an IoT platform, optimising shampoo production times and soap moisture levels. At its Brazil plant, this saves $2.8 million annually through better energy efficiency and productivity.

Tenaris x ABB

Tenaris equipped 400+ electric motors at its Italian steel plant with ABB smart sensors. These provide real-time data on vibrations and voltage anomalies, alerting engineers instantly to prevent failures and costly downtime.

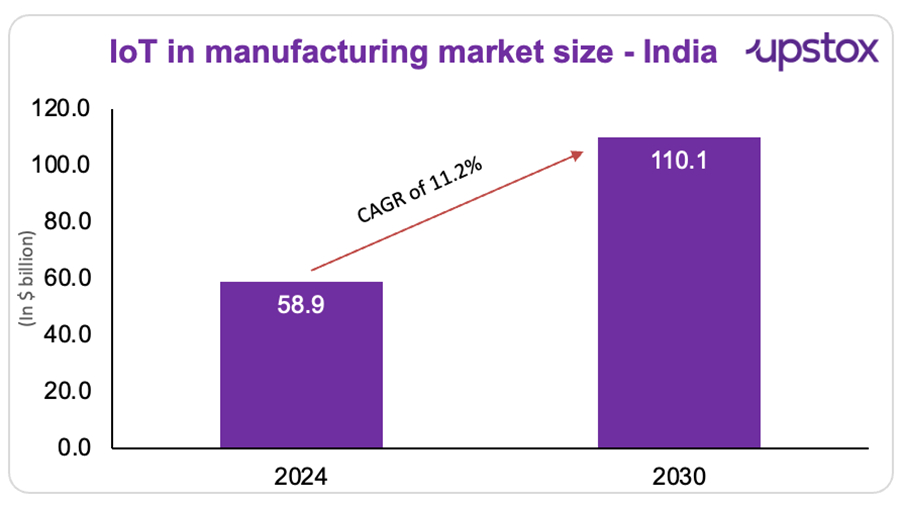

India’s IoT in manufacturing

India’s IoT in manufacturing market, valued at $58.9 billion in 2024, is projected to grow at an 11.3% CAGR till 2030. Indian manufacturers are rapidly integrating AI, 5G, and edge computing, making IoT central to competitiveness, cost control, and sustainability.

Source: Statista

And India is taking active steps to boost it. For example, in June 2025, the Indian Institute of Technology, BHU, has launched a six-month AICTE QIP–PG Certification Programme on IoT and manufacturing. It aims to upskill faculty nationwide in emerging digital and smart manufacturing technologies.

Companies are moving fast too. In June 2025, OnePlus announced a partnership with Optiemus Electronics to locally manufacture IoT products in India under Project Starlight, strengthening its “Make in India” commitment and building a robust domestic manufacturing ecosystem.

Final thoughts

The takeaway? IoT isn’t just another tech buzzword for manufacturing – it’s becoming the backbone of smarter, faster, and greener factories. As the world ramps up talent, innovation, and investments, the next decade could see its factories leapfrog into global leadership. The real question is – are manufacturers ready to harness its full potential and transform how the world builds?

_Disclaimer: This article is for informational purposes only and must not be considered investment advice. Investors should consult with experts before making any investment decisions. _

By signing up you agree to Upstox’s Terms & Conditions

About The Author

Next Story